In the food industry, time and hygiene are everything. Whether it’s processing milk, making sauces, or mixing powders, the job needs to be fast, clean, and consistent. That’s where pumps come in. Pumps in the food industry help move materials like liquids, thick pastes, and even soft solids from one stage to another during production. They make the work easier, reduce manual handling, and keep everything flowing smoothly.

You’ll find pumps in almost every food plant. From transferring juice from one tank to another to blending ingredients in the right proportion, they do a lot of the heavy lifting. Pumps also help maintain hygiene because they allow materials to move without much contact with the outside environment.

Now, let’s take a look at the types of pumps in industry, especially the ones that are most commonly used in food and beverage plants.

Types of Pumps in the Food Industry and its applications

In the food and beverage sector, different types of materials require different kinds of pumps. Some need to handle delicate textures, others need to manage high pressure or temperature.

- Positive Displacement Pumps

These pumps work by trapping a fixed amount of product and pushing it forward. They are good at handling thick materials or items that should not be broken or damaged during movement.

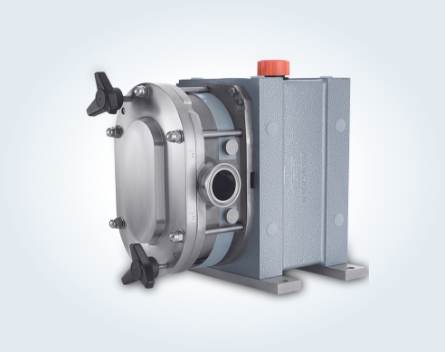

Rotary Lobe Pumps

Fristam rotary lobe pumps belong to this category. They are very gentle to the product, so they are well suited for handling soft and delicate products such as cream, yogurt, or cosmetics. The product is transferred smoothly, so it is not affected in terms of shape and texture during transfer.

Fristam’s FKL pump is equipped with a well-balanced rotor, which enables it to work in high pressure efficiently. The pump is capable of dealing with huge volumes up to 120 cubic meters per hour. It is equally ideal for CIP (Clean-in-Place) and SIP (Sterilize-in-Place) cleaning, which is crucial in food plants to prevent contamination and ensure hygiene.

- Dynamic Pumps

These pumps work differently. Instead of trapping and pushing, they use speed and spinning motion to move the product. These are best for liquids that flow easily.

Centrifugal Pumps

Centrifugal pumps are the most common type in this group. They are best used for thin liquids like milk, juice, and water-based mixtures. Fristam’s centrifugal pumps are known for their high quality and smooth performance. They last a long time, even when used a lot or in tough conditions. These pumps have very small gaps inside (as little as 0.5mm), which allows them to work gently and efficiently without damaging the product.

- Powder Mixers

Besides pumps, powder mixers are also widely used in the food sector. These machines are designed to mix dry ingredients like sugar, flour, or powdered flavors into liquids.

Fristam’s powder mixers are very useful for tasks like blending, dissolving, and making smooth mixtures. They are easy to clean, safe to use, and built to last. These mixers can also be used as portable units, and when connected with the right control system, they can work as part of a fully automated process.

What to look for in a Good Pump for food sector applications

When choosing a pump for the food sector, there are a few important things to keep in mind:

- Clean-in-Place (CIP) and Sterilize-in-Place (SIP) support is a must to keep everything hygienic.

- The pump should move food products gently, without causing any damage.

- It should be energy-efficient and reliable.

- It must be easy to clean and maintain.

- It should be able to handle the amount of product your plant processes every day.

Fristam’s food industry pumps, including positive displacement pumps, centrifugal pumps, and powder mixers, meet all these needs. They are built for hygiene, performance, and flexibility.

Conclusion

Pumps are not just machines, they are the backbone of many food industry operations. From moving milk to mixing powders and transferring sauces, they make everything quicker, safer, and more consistent. Choosing the right pump can improve your product quality, reduce wastage, and save time during cleaning and maintenance.

Whether it’s for moving delicate products or handling high flow rates, there’s a pump out there for every task. With the right equipment, food manufacturers can meet quality standards, keep operations smooth, and scale production without any hassle.

FAQs

Q. Which pump is suitable for the food industry?

A. Centrifugal and rotary lobe pumps are commonly used because they are gentle, clean, and efficient.

Q. What is a pump in the food industry?

A. A pump moves food products like liquids or soft solids from one part of the process to another, helping with faster and cleaner production.

Leave a Reply