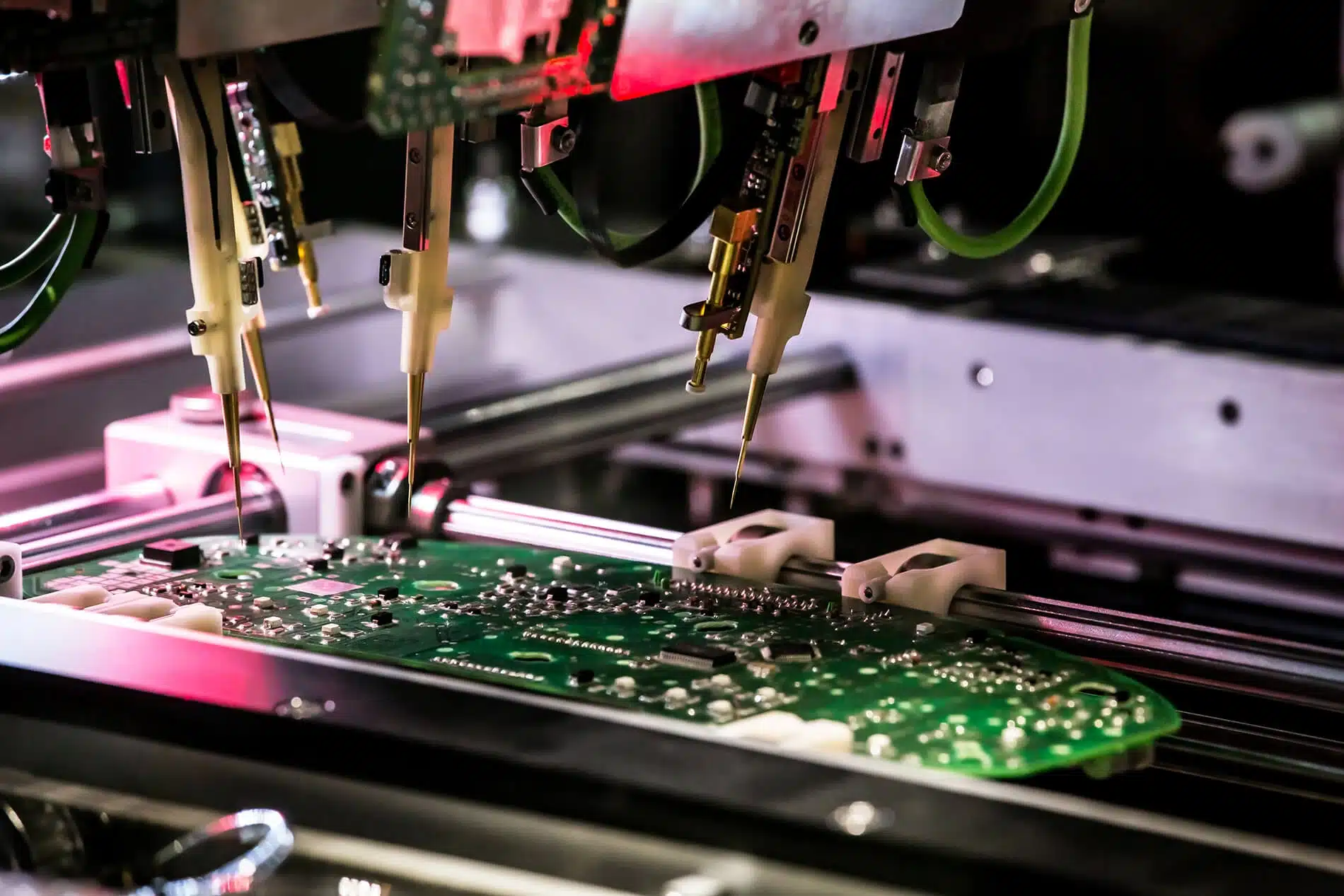

When selecting a reliable printed circuit board (PCB) manufacturer, certifications play a crucial role in evaluating quality, consistency, and compliance with industry standards. Certifications are not just badges — they are proof that the PCBA Factory adheres to global best practices in manufacturing, safety, and quality control. Whether you’re sourcing simple single-layer boards or complex multilayer PCBs, knowing which certifications matter can help you choose the right partner.

In this article, we’ll explore the top certifications to look for in a quality PCB factory, what they mean, and why they matter.

1. ISO 9001: Quality Management System

Why it matters:

ISO 9001 certification is one of the most recognized quality management standards globally. It ensures that the PCB factory follows a structured quality management system, focusing on customer satisfaction, continuous improvement, and operational consistency.

What to check:

Make sure the certification is current and issued by an accredited body. This certification gives you confidence that the manufacturer meets standardized procedures from design through production.

2. ISO 14001: Environmental Management System

Why it matters:

PCB manufacturing can involve chemicals and waste processes. ISO 14001 ensures that the factory follows environmentally responsible practices. It highlights a manufacturer’s commitment to reducing environmental impact and complying with environmental regulations.

What to check:

Look for evidence of proper waste disposal systems, pollution control measures, and efforts to reduce carbon footprint.

3. UL Certification (Underwriters Laboratories)

Why it matters:

UL certification confirms that the materials used in the PCB meet specific flammability and safety standards, especially important for electronics used in high-voltage or heat-sensitive environments.

What to check:

Check if the manufacturer’s PCBs are UL recognized and traceable through a UL file number. This is critical for products entering the North American market.

4. IPC Membership & Compliance

Why it matters:

IPC (Association Connecting Electronics Industries) sets widely accepted industry standards for PCB design, manufacturing, and assembly. IPC-A-600 (for PCB acceptability) and IPC-A-610 (for assembly acceptability) are key standards.

What to check:

Ensure the factory complies with IPC standards and employs IPC-certified inspectors or technicians. This ensures high workmanship and quality across all production stages.

5. IATF 16949: Automotive Quality Management

Why it matters:

For PCB applications in the automotive sector, IATF 16949 is the gold standard. It combines ISO 9001 with additional requirements specific to automotive quality systems.

What to check:

If you’re sourcing PCBs for automotive electronics, this certification ensures the factory meets stringent quality and traceability standards required by automotive OEMs.

6. ISO 13485: Medical Devices Quality Management

Why it matters:

PCBs used in medical electronics must meet strict regulatory and safety standards. ISO 13485 certifies that a factory can consistently produce PCBs for medical devices.

What to check:

Ensure the manufacturer can provide traceability, documentation, and compliance with international health and safety regulations.

7. RoHS Compliance

Why it matters:

Restriction of Hazardous Substances (RoHS) compliance ensures that PCBs are free from toxic substances like lead, mercury, and cadmium. This is essential for environmental safety and legal compliance in many countries.

What to check:

Request a declaration of RoHS compliance and material test reports for reassurance.

8. REACH Compliance

Why it matters:

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) focuses on the health and environmental risks of chemical substances used in manufacturing.

What to check:

Ensure the factory provides documentation confirming compliance with REACH directives for material safety.

Conclusion

A PCB factory’s certifications are more than just paperwork — they reflect the company’s dedication to quality, safety, environmental responsibility, and industry compliance. Whether you’re developing consumer electronics, medical devices, or automotive systems, verifying these certifications can protect your brand and ensure long-term reliability.

Final Tip:

Always ask for copies of valid certificates and verify them through issuing bodies or public databases. Partnering with a certified PCB factory gives you peace of mind and a competitive edge

Leave a Reply